PENTA Mobile Field Service by Penta Technologies, Inc. works with PENTA Enterprise Software.

PENTA Mobile Field Service is a mobile application designed for use by the field technicians of service contractors. The application provides field technicians a list of their assignments, details about each assignment and the associated customer, service history, customer equipment details and history, parts lists, task lists and much more. Field technicians can record customer equipment information, labor, materials, parts, refrigerant usage, tools, field notes and customer sign-off on the device.

Technicians can perform most functions in a disconnected environment without disruption, regardless of network availability. Connection is required for login and data synchronization.

PENTA Mobile Field Service is fully integrated with PENTA ERP and PENTA ECM.

Detail Features:

• My Work List – an easily reviewed list of the technician’s current assignments. Assignments can be work orders, assignments on construction jobs, or overhead tasks like safety meetings and stocking your truck.

• Assignment details.

• Assignment status tracking, visible to the dispatcher when changes are made.

• Customer location details such as address, phone(s), contacts, maintenance contracts and customer or location specific notes.

• GPS mapping of assignments and turn by turn directions.

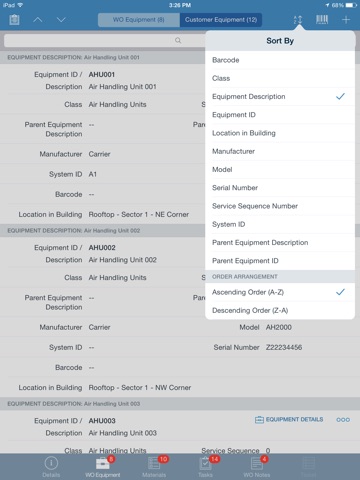

• Extensive, detailed customer equipment information – standard and class specific attributes, equipment notes, warranty information and associated documents such as photographs and spec sheets.

• Ability to update customer equipment information in the field – either adding or changing information on existing equipment or recording new equipment.

• Identification of customer equipment via barcode scanning.

• Location and customer equipment service history.

• Equipment inspection history.

• Assignment task lists and completion tracking.

• Custom inspection questions and answers or task check lists, with branching rules, deficiency identification rules, industry code references, history and more.

• List of materials and parts needed to perform the work.

• Self-scheduling of assignments.

• The ability for a technician to review their personal work history.

• Electronic replacement of the paper work ticket, giving the technician the ability to record:

o Labor (auto generated based on user defined status changes – in route, on site, getting parts, etc.)

o Labor for additional techs

o Parts or materials used, incorporating filtered pick lists and barcodes

o Refrigerant tracking

o Miscellaneous field purchases

o Tool charges

o Customer equipment condition assessments

o Customer equipment meter readings

o Field notes

o Field photographs

o Description of work performed

o Recommended repairs

• Summary presentation to the customer outlining what was done, results, terms and conditions.

• Collection of customer sign off.